Bamboo side-pressed plywood is a versatile and eco-friendly material that offers a unique blend of durability and sustainability. In this article, we will delve into the manufacturing process of bamboo side-pressed plywood and explore its common uses in various industries.

Manufacturing Process: The production of bamboo side-pressed plywood involves a careful process that starts with the harvesting of mature bamboo stalks. These stalks are then cut into precise lengths and thoroughly cleaned to remove any impurities or debris.

After cleaning, the bamboo stalks are sliced into thin strips, typically 3-4mm in thickness. The strips are then boiled in a solution of water and boric acid to eliminate any pests or fungal growth. This treatment process ensures the long-term durability and stability of the final product.

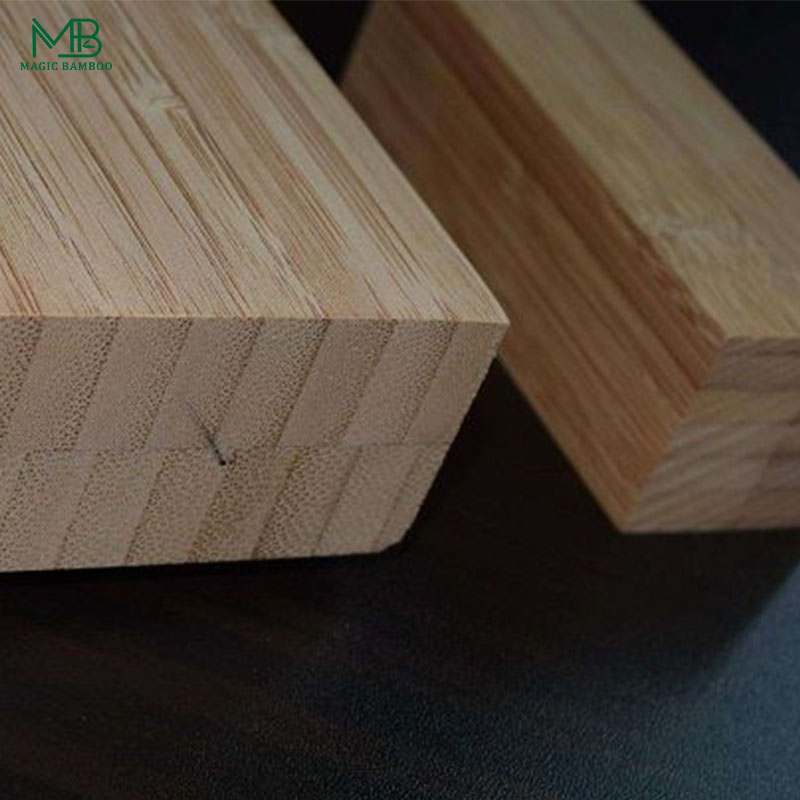

Once treated, the bamboo strips are laid out in a flat and overlapping pattern. The strips are positioned with their sides facing upwards, resulting in the signature side-pressed appearance. High-quality adhesive is then applied between each layer of bamboo strips to create a strong and cohesive bond.

The assembled bamboo strips are then placed in a hydraulic press to apply pressure and heat. This process helps further strengthen the plywood, ensuring a firm and stable end product. After the pressurization is complete, the bamboo side-pressed plywood sheets are trimmed to the desired dimensions and sanded to achieve a smooth surface.

Common Uses: Bamboo side-pressed plywood finds wide applications in various industries due to its unique features. In the furniture industry, it is commonly used for crafting sturdy and visually appealing pieces, such as chairs, tables, and cabinets. Its durability and attractive side-pressed texture make it a sought-after material among furniture designers and manufacturers.

Flooring is another popular application for bamboo side-pressed plywood. It offers a sustainable alternative to traditional hardwood flooring, providing a warm and natural aesthetic to any space. Its strength and resistance to moisture make it ideal for both residential and commercial flooring installations.

In interior design, bamboo side-pressed plywood is utilized for wall paneling, ceilings, and decorative elements. Its distinctive side-pressed texture adds character and depth to any interior space, creating a visually pleasing environment. The eco-friendly nature of bamboo makes it a favorable choice for architects and designers looking to incorporate sustainable materials into their projects.

Bamboo side-pressed plywood undergoes a meticulous manufacturing process, resulting in a durable and visually appealing material. Its versatility and sustainability make it a preferred choice for furniture, flooring, and interior design applications. As the demand for eco-friendly solutions continues to rise, bamboo side-pressed plywood proves to be a reliable and attractive option for both professionals and individuals seeking sustainable alternatives.

Post time: Aug-04-2023